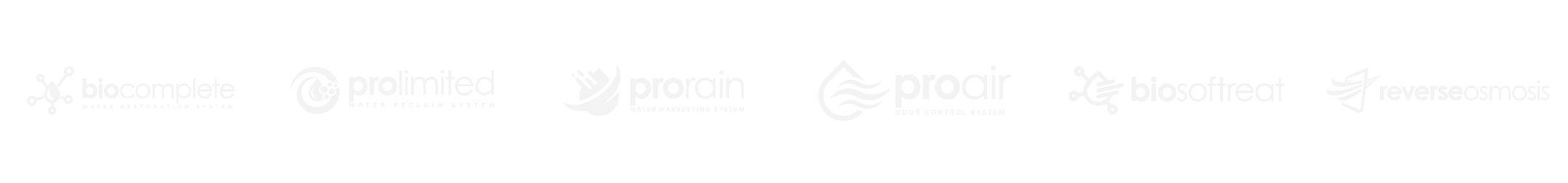

The Bio Complete Water Restoration System is a biological process that uses naturally occurring microbes to remove car wash chemicals out of used water. The resulting clean water can be reused in the car wash.

Products

Solids Separation

Via gravity, solid matter suspended in the water settles to the bottom of a series of tanks. These solids can then be collected and hauled away.

Aeration

Used water enters the aeration tank where oxygen is infused into it. This infusion causes the naturally occurring microbes to switch from their anaerobic to aerobic state. In their aerobic state these microbes give off odorless carbon dioxide (CO2) gas.

Cyclonic Separation

From the aeration tank, the used water is pumped into a series of cyclones that separate out any remaining suspended solids larger than 5 micron (approximately the size of one human blood cell).

Biologic Consumption

After cyclonic separation is complete, the used water enters the bio tank where naturally occurring microbes consume the car wash chemicals.

Clarification

Once the chemicals are removed, the water enters the clarifier tank. At this point, dead microbes settle to the bottom of the tank where they are pumped out daily.

Clean Water Repressurization

The clean water then gravity overflows into the clean water tank where it is stored until it is needed in the wash. On demand, the water is repressurized and sent back to the wash for use.

The Pro Limited is an entry-level water reclaim system that recycles used wash water for reuse. Since the Pro Limited does not contain a biological component for removal of car wash chemicals, the recycled water from this system should only be used in the early stages of a wash.

Solids Separation

Via gravity, solid matter suspended in the water settles to the bottom of a series of tanks. These solids can then be collected and hauled away.

Aeration

Used water enters the aeration tank where oxygen is infused into it. This infusion causes the naturally occurring microbes to switch from their anaerobic to aerobic state. In their aerobic state these microbes give off odorless carbon dioxide (CO2) gas.

Cyclonic Separation

From the aeration tank, the used water is pumped into a series of cyclones that separate out any remaining suspended solids larger than 5 micron (approximately the size of one human blood cell).

Centripetal Separation and Water Repressurization

After cyclonic separation is complete, the used water enters the conical tank where it goes through further separation. The conical tank also acts as a water storage unit, repressurizing the water and sending it back to the wash upon demand.

The Pro-Rain water harvesting system has been specifically designed to be used for the collection of rain water that falls on a location’s roof and/or paved lot. In most cases, the rain water collected will be soft water and will range from pH of 6.5 to 7.5.

Collection

All downspouts and lot drains are plumbed in such a way that the water can flow directly into the underground rainwater storage tank.

Aeration

After the rainwater enters the storage tank, it is infused with high volumes of oxygen. This aeration prevents the rainwater from developing an odor which can form in stagnant water.

Rainwater Repressurization

On demand, the rainwater is pressurized and sent to the wash for use. The system comes with a high/low level float sensor; if low water level is reached, the repress pump will turn off and the system control panel will automatically switch a 3-way valve to city water for all devices running on rainwater.

The Pro-Odor control system utilizes natural forces to prevent re-used wash water from containing an odor when used again in the wash. Traditional methods of odor control are chlorine bleach, air sparger, bubblers or ozone. These systems have all proven to be ineffective for year-round odor control caused by anaerobic bacteria.

The Process

Traditional methods of odor control are ozone, chlorine bleach, and air spargers. These methods have all proven to be ineffective in the process of year-round odor control by anaerobic microbes.

The Pro Air odor-control system includes an aeration blower and intake filter assembly, along with aeration membranes, to infuse high levels of natural atmospheric oxygen into waste water. This changes the environment from anaerobic to aerobic, which allows natural aerobic microbes to consume waste in the water. The byproducts of this waste consumption are CO2 and H2O, which are non-hazardous to humans and contain no smell.

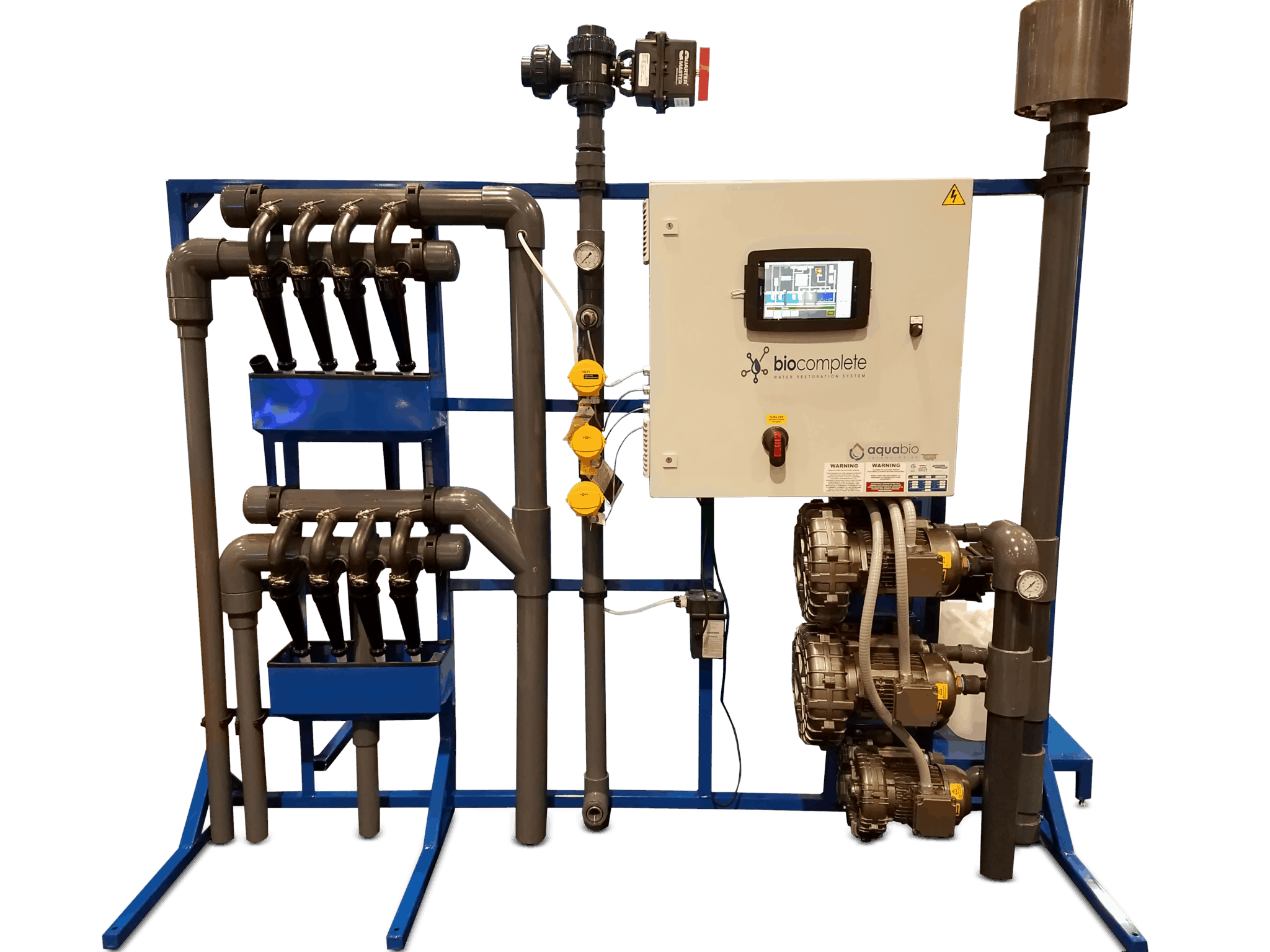

The Bio Softreat system is the first-ever closed-loop biologic water restoration system add-on. With this system, you’ll be able to use biologically restored H2O to produce spot-free rinse water, saving money and helping keep the environment clean. The only fresh water your wash will need will be to replace evaporation and carry out.

Bio Complete Process

The six step Bio Complete Water Restoration process

The Softreat

Water is sent from the Bio Complete clean water tank and sent to the Softreat system.Our Softreat system disinfects the microbes so that the microbes can be filtered out of the water before the water is sent to the reverse osmosis system.

Carbon Filtration

The Carbon filter is used to filter out the disinfection chemical dosed in during the Softreat treat and any chlorine that comes in with the city water.

Anti-Scalant Dosing

The Anti-Scalant dosing system does a chemical injection into the water going to the RO. The Anti-Scalant doesn’t soften the water it merely prevents hard water minerals from sticking to the membranes and the minerals pass out with the reject water from the RO.

Reverse Osmosis

The biologically restored water is then sent through a reverse osmosis system which removes all impurities out of the water. After going through the RO system, the water is held in an RO storage and reject water storage tank.

Repressurization

The water is repressurization from the RO storage tank and sent to the spot free rinse arch.

Aqua Bio reverse osmosis systems are designed for overall superior performance, high recovery rates, minimal energy consumption and offer great savings with low maintenance and operation costs.

RO Controller

Panel mounted with Digital TDS Display. State of the art technology gives piece of mind to the operator.

Frame

Stainless steel welded to a minimal footprint, yet maximizing the accessibility of the system.

Membranes and Housings

Stainless steel housing are home for our high performance membranes handling high flow rates and also an excellent salt rejection rate.

Meters and Gauges

Two (2) flow meters and three (3) pressure gauges panel mounted for easy visibility and accessibility.

Safety and Function

Product float switch, auto membrane flush, low pressure safety shutoff and continuous system performance updates keep the operator informed.

Automatic Restart

In case of power failure or pressure fault, the system will automatically turn back on to ensure continuous production.

Sediment Filter

Accessibility friendly to the operator, the 5 micron sediment filter will help to keep your system functioning as its most efficient level. One additional filter included.

Carbon Filter

Every system includes an auto back washing carbon filter. The filter comes standard mounted to the system on our 9600 (4 membrane) and smaller. Optional mounting for larger systems can be custom ordered.

Contact Us

AQUA BIO TECHNOLOGIES, LLC.

8115 S. Lemont Road Darien, IL 60561

Fax: 630-883-0601