Closed-Loop Water Reclaim Systems: Benefits and Considerations.

Calculating the benefits of collecting and recycling all wash and rinse water.

Water is an important element when it comes to automated carwashing. The car care industry as a whole depends heavily on water access, so daily usage, conservation and discharge have become critical issues over the decades. Since water is so integral, many carwash operators end up asking one question: What are the most effective methods of conserving and recycling the water used in tunnels and bays?

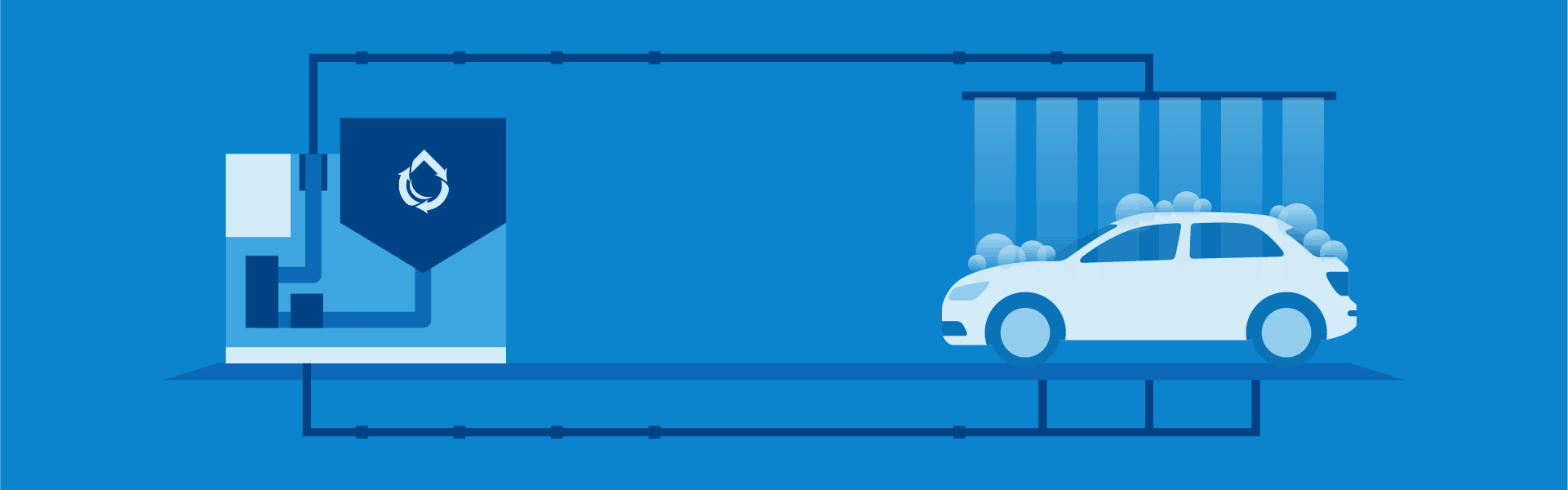

Here, updated reclaim technology may provide an answer to help advance the efficient operation of carwash facilities. Closed-loop water reclaim systems stand ready to provide any owner an option for catching and reusing water from every wash phase and rinse cycle. There is always more to learn about this equipment, and all owners should know best practices for keeping reclaim technology operational, primed and efficient.

Closed-loop factors

As the carwash industry has grown, so have the costs associated with daily water usage. According to John Gibney with Aqua Bio Technologies, municipalities today charge water fees to businesses in two ways: as water comes in and as water goes out. Localities nationwide are looking to generate more income by raising rates for freshwater access and sewer discharge. Depending on how the water is discharged, both the municipalities and the U.S. Environmental Protection Agency (EPA) are imposing regulations. Washes may even be required to clean the water to a certain level before discharge.

“A closed-loop system allows vehicle wash owners a level of self-sufficiency from these rising rates and regulations,” Gibney reveals.

The overall health of the U.S. water and sewer infrastructure is another driver for closed-loop systems usage in carwashes. Many areas of the country have water and wastewater systems that are outdated and in need of repair or replacement, states Denise Wight, vice president of sales with New Wave Industries and PurClean/PurWater. Local municipalities are often overwhelmed, and this leads to an increase in troublesome regulations and restrictions.

Another factor leading to the increased adoption of closed-loop equipment is the technological advancement in reclaim systems that have made them a more attractive option for operators, Wight continues. Also, as real estate has been “gobbled up” by big-box companies and developers, many carwash operators have pursued sites that have no access to a sanitary sewer. Thus, the number of zero-discharge sites will continue to increase in the future.

Common misconception

Even as reclaim education has increased in the industry, Gibney notes that there is a common misconception regarding what constitutes a closed-loop system. People think that closed-loop means self-contained, with no water coming in or going out, but this is not the case. In the vehicle wash industry, there are factors called evaporation and carry out, and calculations show that these can account for 5% to 10% water loss per vehicle. Therefore, any water system must compensate for that loss by taking in more water.

Conversely, if too much water is pushed into the system, the excess water must overflow into a sewer, leech field or excess water holding tank. “When we say zero discharge, we mean minimal discharge,” Gibney explains. “As technologies improve and the need for self-sufficiency from municipalities increases, I see many more vehicle washes moving towards zero discharge.”

Closed-loop technology actually involves treating 100 percent of the water captured in the system to use repeatedly while minimizing water entering and discharging from the system. Gibney states that closed-loop success can only be achieved by removing the used chemistry out of the water on each pass through the system so that it can be used again and again.

Technology advances

This use and reuse of water depends on proper treatment. The technology to achieve closed-loop reclaim has been around for decades, notes Jeff Oyog, engineering and technical support manager with New Wave Industries and PurClean/PurWater. The barriers to installation traditionally were:

- Building systems that were compact enough to fit in a small wash site

- Upkeep requirements that were not simple enough for operators and managers to maintain

- Systems costs that were not low enough for a realistic payback schedule.

“Modern electronics have made automation an affordable reality — and necessary — for ease of maintenance and troubleshooting,” Oyog says. “Small, efficient and affordable options on filtration, and treatments such as ozone to combat bacteria and chemical buildup helped with fitting into realistic site plans.”

Gibney reveals that manufacturers now have the technology to effectively remove used chemicals from captured water. This allows the water to be reused and enables washes to add new chemicals to the restored water. Without this capability, a wash cannot realistically have a closed-loop system. A wash would be repeatedly adding more chemicals to the water to the point where wash quality would suffer immensely. Additionally, restored spot-free rinse water technology has added a new element to systems. An operator can now use restored water to feed a reverse osmosis (RO) system to generate spot-free rinse water.

Selection and installation

Whether an operator is building a new wash, updating an existing wash or planning to rehab an old system, the first step in the closed-loop selection process is understanding the amount of footprint space as well as the resources that are available, according to Gibney. Next, the carwash owner should “research, research, research.” Investigate the systems available today and make sure they are true water restoration systems. One recommendation is talking to other operators using the same brand systems and asking about their experiences.

Choosing a closed-loop system is all about selecting a knowledgeable and experienced water solutions partner, states Melissa Wooten, marketing with New Wave Industries and PurClean/PurWater. With a closed-loop system, it is always important to have support from an experienced professional to ensure the site upgrades, plumbing design and installation go smoothly and are executed in a way that will result in successful water treatment. This support will help a wash avoid long delays, downtime and increased maintenance needs.

A site’s water quality is another factor to consider. The supply water can have a big impact on the closed-loop equipment needed for top quality washing, Oyog notes. If the fresh water supply is not a sufficient quality to use directly for a final rinse, that adds to the list of needed equipment and makes it more difficult to achieve a zero-discharge balance.

“Every site may have its own challenges. Typically, the volume of cars washed is a big factor along with wash equipment,” explains Steve Samudio, technical sales manager with New Wave Industries and PurClean/PurWater. “Knowing the components and how they wash the car can determine the size and/or support equipment that will allow the site to become closed-loop.”

The installation process does not involve much more than installing standard carwash components or systems, but the setup and working with the chemical provider are key, Samudio continues. Making sure the wash provides a clean vehicle with a very minimum amount of fresh water remains the biggest hurdle.

Upkeep suggestions

What upkeep steps should an owner expect after installation? A closed-loop system will clean more particulates out of the wash water, and this means the reclaim tanking will need to be pumped out more often, notes Paul Spence, technical sales manager with New Wave Industries and PurClean/PurWater. The reclaim tanks will fill with dirt faster with a closed-loop system. To save on costs, an owner should check the dirt level in the tank monthly, and when the first tank reaches 1.5 feet of solids at the bottom, an operator should have the tanks pumped out.

Most of the system is automated, but it still needs to be monitored and regularly maintained. Spence recommends that maintenance or upkeep on a closed-loop reclaim system be done via time increments: weekly, monthly, bi-yearly and every two years. The weekly maintenance for a closed-loop system will require approximately 30 minutes, and the monthly steps will take about 45 minutes. The bi-annual maintenance will take longer at around four to five hours, and the maintenance at two years will take approximately six hours.

Samudio further suggests that operators make sure all plumbing and lines to the system are installed properly. Chemistry and water quality must be monitored and above par for wash results to reach maximum efficiency. Monitoring the equipment with daily and weekly checks are a must to prevent potential mishaps or out-of-control usage — water, chemistry, etc.

“Speaking from the standpoint of our systems only, if completely biodegradable chemicals are always used and routine maintenance followed, quarterly nutrients need to be added to the system, and an annual filter change is required,” Gibney says.

Final results

If maintained correctly, the final results provided by closed-loop carwashing should rival conventional wash quality, Oyog states. The path to achieve this quality is not without some increased maintenance requirements and equipment costs. But, these factors should be weighed against the savings of reduced water and sewer costs to determine the feasibility and profitability of closed-loop operation.

Ideally, a closed-loop wash is using completely biodegradable chemicals, operating a true restoration system that removes chemicals from the water and following the manufacturer’s required maintenance, Gibney concludes. If so, customers will not be able to tell any difference in wash quality compared to the use of fresh water.

By Jonathan Abrams is a freelance contributor.

About Aqua Bio Technologies, LLC

Founded in 2010, Darien, Illinois-based Aqua Bio Technologies is a leading provider of innovative biologic restoration, water reclaim, rain harvest, odor control and reverse osmosis (RO) systems. None of its solutions use ozone, UV, or chemicals of any kind to control odor – only nature. As the manufacturer of the first vehicle wash industry closed-loop water treatment system, the company is able to deliver a substantial savings in time and money to its customers with dramatic reductions is water and sewer costs.

For more information about Aqua Bio and how our systems are designed to save you and your car wash a ton of money by reusing 100% of the water collected contact us today.

877.881.9141 | info@aquabio.co | Facebook | LinkedIn | Twitter.